Flood Defense Group supports the USACE and New Mexico National Guard in the deployment of HESCO flood barriers in recent burn scar areas and showcased an impressive collection of unique product modifications

Follow Us

10 Street Name, City Name

Country, Zip Code

555-555-5555

myemail@mailservice.com

Flood Defense Group supports the USACE and New Mexico National Guard in the deployment of HESCO flood barriers in recent burn scar areas and showcased an impressive collection of unique product mod...

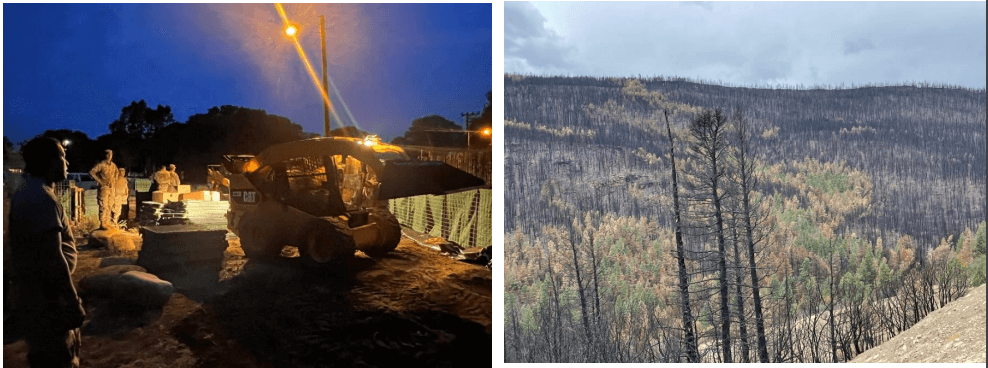

Flood Defense Group is using HESCO Flood Barriers for wildfire debris flow and flood protection wildfire burn scar areas in Las Vegas and Mora New Mexico. This is in support of the USACE and the New Mexico National Guard. The flood defense barriers were deployed to prevent flooding and the damaging effects associated with debris flows impacting the local community and infrastructure.

When it comes to protecting against debris flows that occur within a burn scar area, HESCO flood barriers are one of the best options in the industry for wildfire debris flow and flood protection within wildfire burn scar areas. This is because HESCO flood barriers have the ‘bulk’, or mass, that allow them to protect against the damaging effects of a debris flow. This is one of the most dangerous types of flooding encountered in the USA because they are violent and can carry significant debris in the form of mud, rocks, branches, and even trees which will impact the flood barriers. Also, due to the mud and debris within the water, debris flows are actually heavier than ‘normal’ flood water, generally flow quite quickly, and leave a trail of damage in their wake.

In this deployment, Flood Defense Group assisted with the supply and installation of flood barriers in Las Vegas and Mora, New Mexico. Similar to other scenarios where we needed to provide protection against debris flows, the first areas to be protected against flooding were multiple wastewater treatment sites as well as pump stations for local drinking water. This is to protect drinking water from contamination by floodwater intrusion as well as to protect water treatment facilities from being flooded and causing the ecological disaster of open wastewater being washed down a river. These are two of the most common concerns and first pieces of infrastructure to protect when living in the shadow of a new burn scar area. The threat of debris flows, and flooding can be expected to persist for years after a forest fire event.

In this deployment, Flood Defense Group assisted with the supply and installation of flood barriers in Las Vegas and Mora, New Mexico. Similar to other scenarios where we needed to provide protection against debris flows, the first areas to be protected against flooding were multiple wastewater treatment sites as well as pump stations for local drinking water. This is to protect drinking water from contamination by floodwater intrusion as well as to protect water treatment facilities from being flooded and causing the ecological disaster of open wastewater being washed down a river. These are two of the most common concerns and first pieces of infrastructure to protect when living in the shadow of a new burn scar area. The threat of debris flows, and flooding can be expected to persist for years after a forest fire event.

Throughout the process of deploying the HESCO flood barriers around a number of sites, there were numerous examples on display of how it is possible to modify this product. Many of these modifications are simple to accomplish but generally unknown techniques. Due to the variety of modification techniques used during this deployment, we decided to document these examples in order to easily display some capabilities of the HESCO flood barrier and how it can be uniquely tailored to provide a variety of solutions during a flood barrier deployment.

Below, are some pictures and examples of the deployment of the HESCO flood barrier as well as some unique modifications we were able to do with the product during this deployment.

Modification of Product Thickness to Fit Footprint

This an example of how you can modify a HESCO flood barrier to make it thinner. In this case, we were installing flood barriers at the Las Vegas water treatment facility and found that the HESCO was 6” thicker than the base it was supposed to sit on. The solution was to unscrew the helical coils on one side of the entire stretch where the barrier did not fit, move the face panels inward by 6”, and re-screw the helical coils back into place such that the thickness of the barrier was 6” thinner.

NOTE: Some staples within the geotextile needed to be pulled out during this process to allow the face panels to move inward. The geotextile was not cut during this process. We did go back and cut out the extra 6” of wire mesh that can be seen protruding

Modification of HESCO Face Panels Around Electronic Infrastructure

Similar to the modification above, we had a requirement to push back a single face panel of the HESCO barrier in order to allow access to entry control electronics. This is a fantastic example of how you can move a single face panel of the HESCO when working around obstructions like this.

Modified HESCO to Create a Rock Gabion for Scour Protection

This is a great example of how you can completely take apart a HESCO barrier create something totally different by using the coils and wire mesh. In this case, we cut the wire mesh panels wrapped/screwed them around the guard rail posts to act as an anchor which we then attached HESCO panels to and filled with rock like a traditional ‘gabion’. This was done because there was serious erosion and loose soils at the base

of the flood barrier on the road above creating a significant vulnerability of scouring and undermining of the flood barrier. By doing this, we were able to further protect the slope from failure during a flood event by providing scour protection.

Modified HESCO Face Panel to Connect 2 Sections of HESCO

This is one of our most common modifications. During a HESCO flood barrier deployment, it is common to have multiple crews building HESCO at multiple sections of a floodwall at the same time. There will often come a time when two sections need to be connected which generally calls for a ‘modified face panel’. You can see how a face panel was cut to fit and subsequently attached using the helical coils at the connection points.

NOTE: Make sure there is extra geotextile on either side of this modified panel. This extra geotextile overlaps the area of the join within the barrier so there is no loss of fill material out the corners during the filling process. We will use zip ties to secure these geotextile flaps into place on either end of the modified panel during the filling process.

Modified HESCO to Protect Sewage Pipes Against Debris Impact

This is one of our most unique, non-traditional applications of this product during a flood event and is a great testament of how this product can be taken apart and reassembled to creatively solve challenging problems.In this case, there was a sewer pipe below a pedestrian bridge that had been damaged from floodwater and debris impact in the past. With monsoons coming and a very real threat of imminent flooding, it was important to devise a way to protect this sewer pipe from damaging debris impacts during a flood event from both the side and below. To solve this problem, the HESCO was completely taken apart and clad to the side of the bridge, securing it with zip ties, tie wire, and parachute chord. To protect the pipe from below, we were able to wrap/screw sections of wire mesh around the steel beams on either side at the bottom of the bridge as an anchor for additional wire panels to span below the bridge. This was designed to mitigate against floating debris from going under the bridge and somehow damaging the pipe by getting stuck or wedged against the pipe during a flood event.

NOTE: This example of wrapping the wire mesh around the steel beams of the bridge using wire/coils is similar to the gabion example above where we were able to wrap the wire mesh around the guard rail posts. In both of these examples, wrapping the wire around fixed objects can provide wonderful ‘anchor points’ when getting involved in unique modifications like this

Modified HESCO to Tie Into a Raised Levee or Berm

We regularly have to tie the HESCO flood barrier into existing levees or berms. Normally, there are two common methods of doing this.

- Dig a keyhole into your berm and backfill around your barrier upon completion

- Modify the HESCO Bastion by cutting it down to size such that it appears to disappear into the berm without digging into the berm at all

It is our preference to go with option 2 and not dig into a berm or levee. We modified the HESCO Bastion to conform it to the earthen berm. This is easily done by taking a new unit of HESCO Bastion and completely disassembling it. This will allow you to modify/cut the material and reconnect it one cell at a time while you conform it to the embankment you are tying into.

We prefer to use the modification technique because there is generally vegetation (root structures) on/within the berm which are all great additions to prevent erosion of the berm during a flood event. Digging into a berm creates a vulnerability for erosion because swirling water during a flood event will quickly erode any exposed or loose soils.

NOTE: Also, when working on or around USACE levee systems, it is generally unacceptable to dig into them in any way which creates an additional reason to go with the modification technique which we prefer anyway.

NOTE: Freshly disturbed dirt is prone to erosion from moving water during a flood event. This is also why we did not want to dig into the berm. If you ever do dig into a berm and have freshly disturbed soil, it may be wise to cover it with stone which is helpful in preventing erosion from floodwater during a flood event as water starts swirl around the area.

Gap Closures with HESCO Bastion

Sometimes, it is important to maintain access to a building when surrounding it with flood barriers. Often, when preparing for an anticipated flood that may take a long time to arrive, there is a need to maintain access to a building or location while also being able to seal it off quickly prior to incoming flood waters. This is an example, where we were able to completely surround a water treatment facility while also leaving access to it. This was done by simply leaving a small section of the HESCO Bastion empty while also making sure the length of these empty cells is the correct length to simply close the gap by pinning these empty cells to the opposite side of the gap and thus ‘close the gap’ immediately prior to a flood. Common examples include:

– Gap closures to leave access to buildings

– Gap closures to leave roads and railroad tracks open until the last minute

– Gap closures anywhere you would want to pass through a flood barrier during times

when flooding is not expected.

The robust protection of HESCO and ability to quickly seal off a gap closure is a primary reason why Flood Defense Group uses HESCO Flood Barriers for wildfire debris flow and flood protection wildfire burn scar areas.

Irregular Tie-in

Normally, we always make sure to join the HESCO flood barriers at the coils with the pins provided. Sometimes, there are obstructions that prevent the HESCO from being joined properly. In this case, there was a fence that the property owner did not want to cut so we worked around it. You can see how we butted the HESCO flood barriers as close together as we could on either side of the obstruction (a fence) and proceeded to fill the HESCO cells on either side. During the filling process, the end panel of the HESCO expanded slightly which reduced the amount of space that water can pass through. We then used spray foam to seal this gap. Spray foam is extremely effective at closing gaps or sealing points of potential seepage within a flood wall and a fantastic tool to have on hand!

Honorable Mentions – HESCO Bastion Flood Barrier Modifications

The flood barrier deployments in New Mexico displayed several examples of how you can modify a HESCO flood barrier as detailed above. With so many examples of how to modify a HESCO flood barrier, we are listing a couple additional examples that were not used during this flood barrier deployment but are worthy mentions within such a comprehensive list of different ways you can modify the product. There are additional examples not listed but here are a couple honorable mentions.

Modified HESCO to create a seal around pipes We enjoy working with this product in difficult locations such as this because it is easy to modify for a good fit when the situation requires. In this example, the barrier had to transition through the pipes pictured and into the berm on the left side of the photo. The photos below show the steps to take when it is necessary to work around pipes or similar obstructions that cannot be moved.

Step 1 – We started by placing a unit of HESCO Bastion on either side of the pipes as seen in the photo to the left and the photo below.

Step 2 – Wire the two units together around the pipes to be sealed. This can be done in a variety of different ways but in this example, we did the following steps:

A) We cut two strips of a single square strip of the welded wire mesh and attached it vertically to the HESCO Bastion units on either side of the pipes as shown

NOTE: These strips allow you working space and an anchor point for step B

B) We then cut strips of welded wire mesh which were transitioned from side to side and between the pipes

C) Use a coil on either side of the pipes to screw the vertical and horizontal wire panel pieces together therefore connecting the HESCO Bastion on either side and between the pipes.

Step 3 – Line your modified cell with geotextile fabric and carefully fill the dirt/sand up and around the pipes making sure the geotextile forms a complete seal around the pipe and that fill material cannot escape. Compact the fill material in 1’ lifts throughout the filling process.

NOTE: We normally do not use water to create compaction but in this case, we did use water to ensure the sand was consolidated and well compact around the pipes throughout this cell prior to stacking the 2-layer high HESCO Bastion.

Step 4 – Spray Foam Seal for Good Measure In this case, because of the number of pipes, we felt a layer of spray foam around the point of entry of the pipes into the HESCO Bastion was a good idea as the foam is a great tool in sealing up areas where seepage may occur during a flood event.

NOTE: Don’t forget, Spray Foam is a wonderful tool in sealing up gaps that may occur within your flood defense perimeter!

Modified HESCO to create additional stability or support to a wall

When you are building HESCO flood barriers for wildfire debris flow and flood protection wildfire burn scar areas, we like how simple it is to add stability in the form of extra cells anywhere within your floodwall. It is simple and inexpensive to install ‘buttress walls’ or ‘buttress cells’ to a line of HESCO Bastion for added stability as desired. The photos above show how we were able to take a few cells and attach them to main line of HESCO Bastion close to where the floodwall ties into to an earthen berm on either side of the facility being protected for some easy reinforcement at this tie-in point. Perhaps this could be considered ‘overkill’, but the speed and ease associated with simply adding some buttress cells along the way gives us added comfort when floodwaters arrive and are near the top of your barrier! These buttress cells can be added during construction or even years later as desired.

Conclusion:

HESCO Bastion was a great fit for this deployment and the description of our modifications to the HESCO Bastion product during construction detailed above are designed to give possible end users an idea of product capability should you have a similar situation. We understand that modifications of HESCO Bastion (or any flood defense barrier) are ‘done at your own risk’, but we regularly modify the HESCO Bastion product if/when required to suit the location with great and continued success. This description is for general knowledge and understanding of our work with the HESCO Bastion product which may prove helpful during the evaluation of this product for potential end users. It’s an amazing product that provides peace of mind when faced with the potential of imminent flooding and damaging debris flows!

Finally, we would like to provide an honorable mention to the USACE for mobilizing the planning and resources in reacting to the flood vulnerabilities resulting from New Mexico wildfires and the New Mexico National Guard for their tireless efforts to quickly implement the plan. The time from identifying the flood threat to deploying a flood defense plan was amazing and Flood Defense Group always enjoys helping out and using HESCO Flood Barriers for wildfire debris flow and flood protection within wildfire burn scar areas.

If you are dealing with potential floodwaters, Flood Defense Group remains available to be reactive in providing support!

www.flooddefensegroup.com

1-208-585-1815